A TWO AXIS SOLAR TRACKING SYSTEM TO TRACK SUN RAYS

Overview

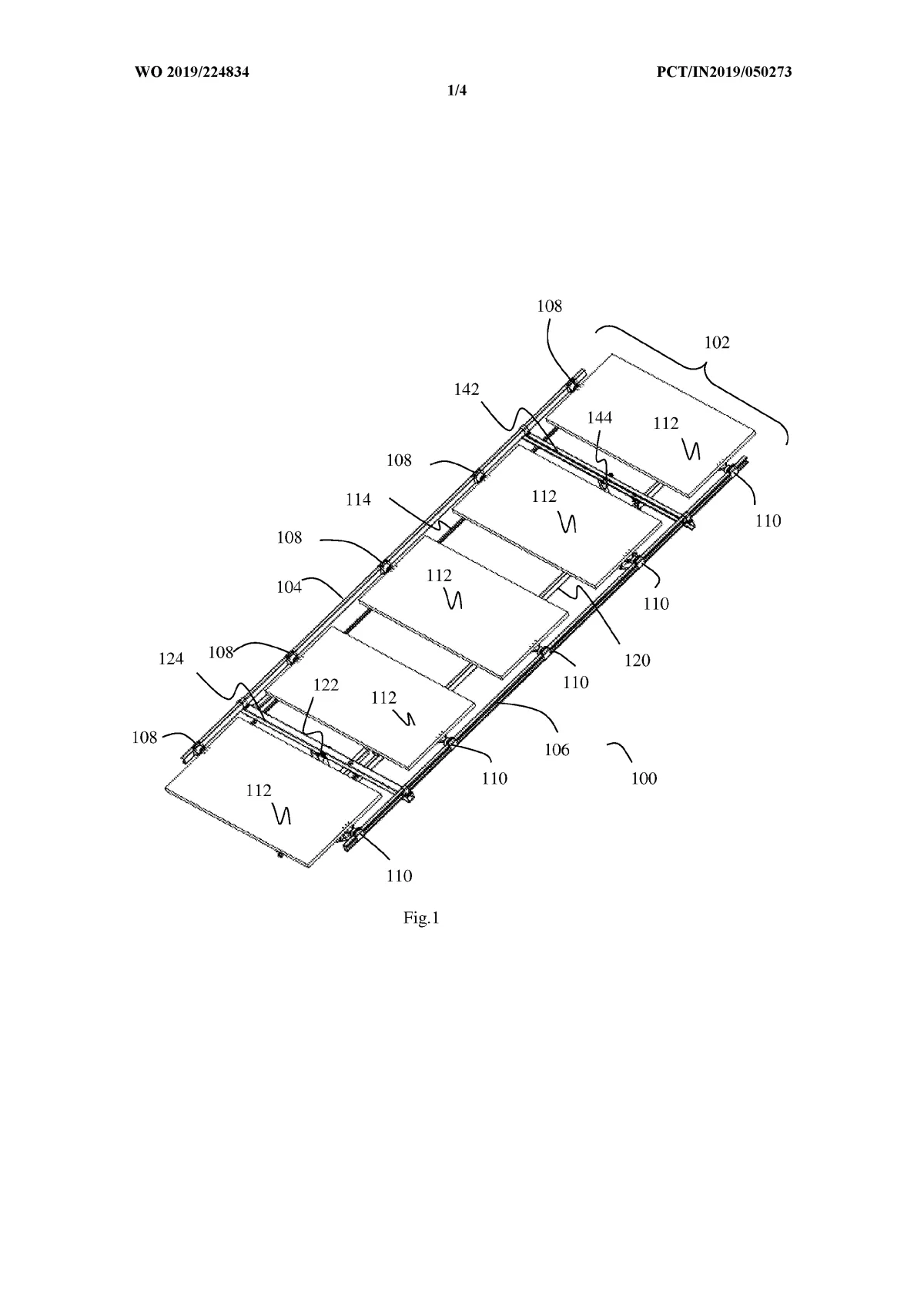

The invention relates to a solar panel mounting system that automatically follows the sun’s position throughout the day and across seasons.

Problem

Conventional fixed-tilt structures and common single-axis trackers cannot keep solar panels aligned with the sun at all times. This reduces energy generation, especially during seasonal changes. Traditional dual-axis trackers improve performance but are often heavy, complex, and expensive to deploy at large solar plants.

Solution

The patented system introduces a simplified dual-axis solar tracking structure that adjusts panel orientation in two directions using a mechanically efficient linkage and actuator arrangement, providing higher energy capture while remaining practical for large-scale installations.

Key Features

- Two-direction tracking (daily east-west and seasonal north-south movement)

- Four-bar linkage mechanism converting linear motion into rotation

- Rail-beam and strut based movement instead of heavy gear systems

- Microcontroller-based automatic sun-tracking control

- Modular structure designed for ground-mounted solar farms

Benefits

- Increased energy generation compared with fixed or single-axis systems

- Lower mechanical complexity than conventional dual-axis trackers

- Reduced maintenance and installation cost

- Suitable for utility-scale solar projects

Claim-Based Protection

The patent protects the structural arrangement of beams, struts, joints, and actuators that enable controlled dual-axis movement of solar modules using a simplified mechanical linkage system.

The Problem the Invention Addresses

Solar panels generate the most electricity when they directly face the sun. However, the sun’s position constantly changes — it moves across the sky during the day and shifts north-south across seasons throughout the year. Most solar installations cannot continuously maintain the best angle toward the sun.

Today, the industry mainly uses three types of mounting approaches:

- Fixed-tilt structures

- Panels remain at one angle all year.

- Simple and low cost

- But they lose a large amount of potential energy because they are rarely aligned with the sun

- Single-axis trackers (commonly used in utility solar plants)

- Panels rotate only east-west during the day.

- Improves generation compared to fixed systems

- Still inefficient during mornings, evenings, and seasonal shifts (winter vs summer)

- Traditional dual-axis trackers

- Panels follow the sun in both daily and seasonal directions.

- Best energy output

- However, they are mechanically complex, heavy, expensive, and difficult to maintain at large scale

Because of this, solar developers face a major trade-off:

- Affordable systems → lower energy output

- High-performance systems → too costly and complicated

As solar tariffs decline worldwide, projects must produce more electricity per installed megawatt to remain financially viable. The industry needs a solution that delivers near dual-axis performance without the cost, weight, and maintenance burden of conventional dual-axis machines.

In simple terms:

There is no practical system today that combines high energy generation with low mechanical complexity and scalable cost. This gap directly impacts project profitability, land usage efficiency, and long-term operational reliability in large solar farms.

The invention is designed specifically to solve this performance-versus-cost conflict.

The Invention — The Solution to the Problem

The invention provides a mechanically simplified dual-axis solar tracking system that automatically keeps solar panels aligned with the sun throughout the day and across seasons, while remaining practical for large-scale solar installations.

Instead of using heavy rotating platforms, complex gearboxes, or large torque tubes like conventional dual-axis trackers, the system uses a smart structural arrangement that converts simple linear movement into controlled panel rotation.

How the Solution Works

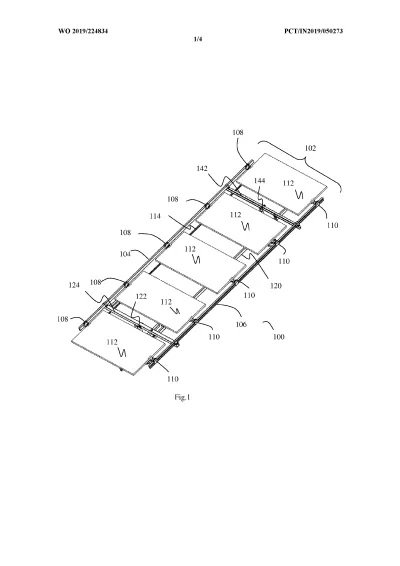

The solar modules are mounted on a frame supported by ground-fixed pillars. Two independent movements are created:

- East-West (daily sun movement)

- A rail beam and actuator move linearly and rotate the module frame horizontally so the panels follow the sun from morning to evening.

- North-South (seasonal sun movement)

- A second rail beam connected through struts adjusts the tilt angle of the frame, allowing seasonal alignment as the sun shifts across the year.

These motions are achieved through a four-bar linkage mechanism, which transforms actuator motion into smooth angular movement. Spherical joints allow flexibility and maintain alignment even on uneven terrain.

A microcontroller-based control system automatically positions the panels using programmed solar path calculations. Multiple tracker rows can be synchronized, reducing control and drive complexity.

Key Characteristics of the Solution

- Dual-direction tracking using simple linear actuators

- Mechanical linkage replacing complex rotating machinery

- Balanced structural geometry for stability

- Modular construction suitable for large solar farms

- Automatic sun-tracking control

Result

The invention delivers the energy-capture advantages of dual-axis tracking while avoiding the cost, weight, and maintenance challenges that previously prevented widespread deployment at utility scale.

In practical terms, it bridges the gap between low-cost single-axis trackers and high-performance dual-axis systems by combining improved energy yield with scalable installation economics.

The Gap in Prior Art

Existing solar mounting technologies force project developers to choose between performance and practicality:

- Fixed-tilt systems

- Low cost and simple, but large energy losses because panels cannot follow the sun.

- Single-axis trackers (industry standard)

- Track the sun only during the day (east–west).

- They still lose substantial energy during mornings, evenings, and seasonal changes when the sun’s height varies.

- Conventional dual-axis trackers

- Provide the best energy output by following the sun in both directions.

- However, they rely on heavy rotating structures, gear mechanisms, and complex drive systems.

- As a result, they are:

- Expensive to manufacture and install

- Difficult to maintain

- Structurally heavy and less reliable for large solar farms

Because of these limitations, dual-axis tracking has not been widely adopted at utility scale despite its energy advantage.

The Missing Solution

The industry lacked a system that could:

- Deliver near dual-axis energy performance

- Maintain mechanical simplicity

- Be cost-effective for large solar plants

- Reduce maintenance and structural complexity

How the Invention Fills the Gap

The patented system introduces a structurally simplified dual-axis tracker using a linkage-based mechanism and linear actuation instead of complex rotating machinery. This enables dual-direction solar alignment while remaining practical and scalable for commercial deployment.

In short:

The gap was the absence of a commercially viable, large-scale dual-axis tracking solution combining high energy yield with manageable cost and mechanical simplicity — which this invention directly resolves.

Unique Features of the Invention

Mechanically Simplified Dual-Axis Tracking

Provides both east-west (daily) and north-south (seasonal) solar tracking using a structurally simple arrangement rather than complex rotating platforms.

Four-Bar Linkage Motion Conversion

Converts linear actuator movement into controlled angular rotation of the solar module frame, eliminating the need for heavy torque tubes and large gear assemblies.

Rail-Beam and Strut Drive Architecture

Uses moving rail beams and struts connected through spherical joints to create smooth multi-directional movement and maintain alignment even on uneven terrain.

Reduced Mechanical Complexity

Avoids traditional gearboxes, drive shafts, and heavy rotating foundations commonly used in dual-axis trackers, lowering maintenance requirements.

Independent Yet Coordinated Two-Direction Control

Separate actuators manage daily tracking and seasonal tilt, allowing precise positioning and operational flexibility.

Microcontroller-Based Automatic Positioning

Integrated control system calculates solar position and automatically adjusts panel orientation without manual intervention.

Modular and Scalable Design

Multiple tracker rows can be synchronized and operated using a simplified control architecture suitable for large solar farms.

Balanced Structural Geometry for Stability

The linkage structure distributes loads efficiently, improving wind resistance and structural reliability.

Wide Tilt Range Capability

Allows significant seasonal angle adjustment to improve annual energy capture.

Distinctiveness

The uniqueness lies in achieving dual-axis tracking performance using a lightweight, linkage-based mechanical structure rather than traditional heavy rotating mechanisms — combining high energy efficiency with practical large-scale deployability.

Industries where the invention can be useful?

Utility-Scale Solar Power Plants, Commercial & Industrial (C&I) Solar Installations, Renewable Energy Equipment Manufacturing, Energy & Infrastructure Investors, Agriculture & Rural Electrification, Government & Public Infrastructure, High-Performance Solar ApplicationsAn estimate of the total addressable market?

Market Size — Total Addressable Market (TAM) This patent relates to solar tracking systems, which are a core component of ground-mounted solar power plants. Therefore, the realistic TAM is derived from two overlapping markets: The global solar power generation market The solar tracker equipment segment (direct product category) 1. Direct Product Market (Solar Tracker Market) The global solar tracker market was valued at approximately USD 4.4 billion (2022) and is projected to reach about USD 29.3 billion by 2030 Other industry forecasts estimate USD 10.3 billion (2024) → USD 22.9 billion (2029) Long-range projections indicate continued expansion to well above USD 40+ billion by early 2030s Conclusion (Direct TAM): ➡ Roughly USD 20–30+ billion global addressable market this decade for solar tracking systems alone. 2. Deployment Capacity Opportunity (Installed Base Potential) Around 752 GW of solar trackers are expected to be installed globally between 2024–2030 Utility-scale solar dominates new installations (over half of global additions) This matters because the patented technology specifically targets utility-scale and large installations, the fastest-growing segment. 3. Parent Industry Market (Upper TAM Boundary) Global solar PV market projected to reach ~USD 609 billion by 2030 Trackers are a core balance-of-system component in large plants, meaning adoption scales directly with solar expansion. Commercial Interpretation Primary TAM (direct licensing target): Solar tracker manufacturers & mounting system suppliers → ~$20B–$30B+ Secondary TAM (ecosystem exposure): Utility-scale solar plant development → hundreds of billions in projects In Simple Terms: As solar farms rapidly expand worldwide, almost every large installation needs tracking technology. This invention participates in a multi-billion-dollar hardware market that is growing quickly because higher energy output is now critical for project profitability.Potential Customers/End Users. Who might benefit?

Potential Customers / End Users The invention benefits organizations involved in building, supplying, or operating solar power systems where higher energy output improves project returns. 1. Solar Project Developers & Power Producers Independent Power Producers (IPPs) Utility-scale solar farm developers Renewable energy project owners Government solar project agencies Benefit: Higher electricity generation and improved project profitability. 2. EPC Contractors (Engineering, Procurement & Construction) Solar EPC companies building large plants Turnkey renewable infrastructure contractors Benefit: Ability to offer higher-performance plants as a competitive advantage in bids. 3. Solar Tracker & Mounting Structure Manufacturers Solar tracker manufacturers Module mounting structure suppliers Balance-of-system hardware manufacturers Benefit: Integrate the patented mechanism into product lines to offer differentiated performance. 4. Commercial & Industrial Energy Users Manufacturing plants Warehouses and logistics parks Data centers Large commercial campuses Benefit: More power generation from the same installation area, reducing electricity costs. 5. Energy Investors & Asset Operators Renewable energy funds Infrastructure investors Solar asset operators and O&M companies Benefit: Increased energy yield improves long-term return on investment. 6. Specialized Deployment Segments Agrivoltaic installations Remote or off-grid power systems Land-constrained projects Benefit: Maximizes energy production where land or infrastructure is limited. In simple terms: Anyone who builds, sells, or operates large solar installations can use this technology to produce more electricity from the same panels and land area.Actions

Added all portfolio

| Country | Current Status | Patent Application Number | Patent Number | Applicant / Current Assignee Name | Title | Google Patent Link |

| Canada | Granted | 3100975 | 40421 | Varun Sachar | A SOLAR TRACKING SYSTEM | Google patent link |

You may also like the following patent