Novel separator material for Solid-State Battery

This invention introduces a novel separator for solid-state batteries made from recycled PET (rPET) modified with waste oyster shell powder. This composite material offers high mechanical strength and thermal stability, effectively suppressing lithium dendrite growth to prevent short circuits. Compared to expensive ceramic separators, it achieves an excellent balance of performance, cost-efficiency, and environmental sustainability.

Traditional battery separators (PE) melt at low temperatures (below 120°C) and cannot stop lithium dendrites from causing short circuits and fires. Current solid-state solutions face a dilemma: ceramic separators (e.g., LLZO) are safe but brittle and expensive, while polymer options (e.g., PEO) suffer from poor thermal stability and low mechanical strength at high temperatures. There is a critical need for a tough, safe, and cost-effective material.

The solution integrates a recycled PET (rPET) matrix with rigid oyster shell powder. These natural particles disperse mechanical stress and increase interface contact pressure, leading to more uniform ion transport and delayed thermal runaway. Simulations show that this material raises the thermal runaway threshold to 180°C. With a mechanical strength score of 8.5/10 and a dendrite suppression rating of 8.0/10, it matches the performance of premium ceramic separators at a fraction of the cost.

It solves the flaws of brittleness and high costs found in prior art. Unlike ceramic separators that crack easily during assembly, the rPET matrix provides the necessary toughness to handle volume changes during battery cycles. Furthermore, it addresses environmental concerns by transforming industrial and ocean waste (oyster shells and plastic bottles) into high-performance battery components, creating a truly circular economy solution.

The major gap in prior art was the lack of a "Sustainable High-Performance Separator." Previously, manufacturers had to choose between low-cost but unsafe plastic films or safe but expensive and fragile ceramics. This invention bridges that gap by using bio-mineralized fillers and recycled polymers to deliver industrial-grade safety and performance while significantly reducing the carbon footprint and material cost of solid-state batteries.

- High-performance dendrite suppression: Rigid oyster shell particles effectively block lithium dendrite penetration.

- Excellent thermal stability: Thermal runaway is delayed to 180°C, significantly improving safety.

- Balance of mechanical strength and toughness: The rPET matrix provides flexibility, preventing the brittleness issues associated with ceramic-based separators.

- Environmentally friendly and low-cost: Made with 100% recycled materials and biowaste, its cost is far lower than LLZO.

Industries where the invention can be useful?

Electric Vehicles (EVs): Next-generation, highly safe, long-range solid-state battery packs. Energy Storage Systems (ESS): Large-scale grid or home energy storage, emphasizing low cost and thermal safety. Consumer Electronics: Ultra-thin, explosion-proof batteries for smartphones and laptops. Aerospace and Military: Power sources operating in extreme temperatures.An estimate of the total addressable market?

$13 billlionPotential Customers/End Users. Who might benefit?

Electric Vehicles (EVs): Next-generation, highly safe, long-range solid-state battery packs. Energy Storage Systems (ESS): Large-scale grid or home energy storage, emphasizing low cost and thermal safety. Consumer Electronics: Ultra-thin, explosion-proof batteries for smartphones and laptops. Aerospace and Military: Power sources operating in extreme temperatures.Documents

-

1766220643128_938.pdf

Actions

Added all portfolio

| Country | Current Status | Patent Application Number | Patent Number | Applicant / Current Assignee Name | Title | Google Patent Link |

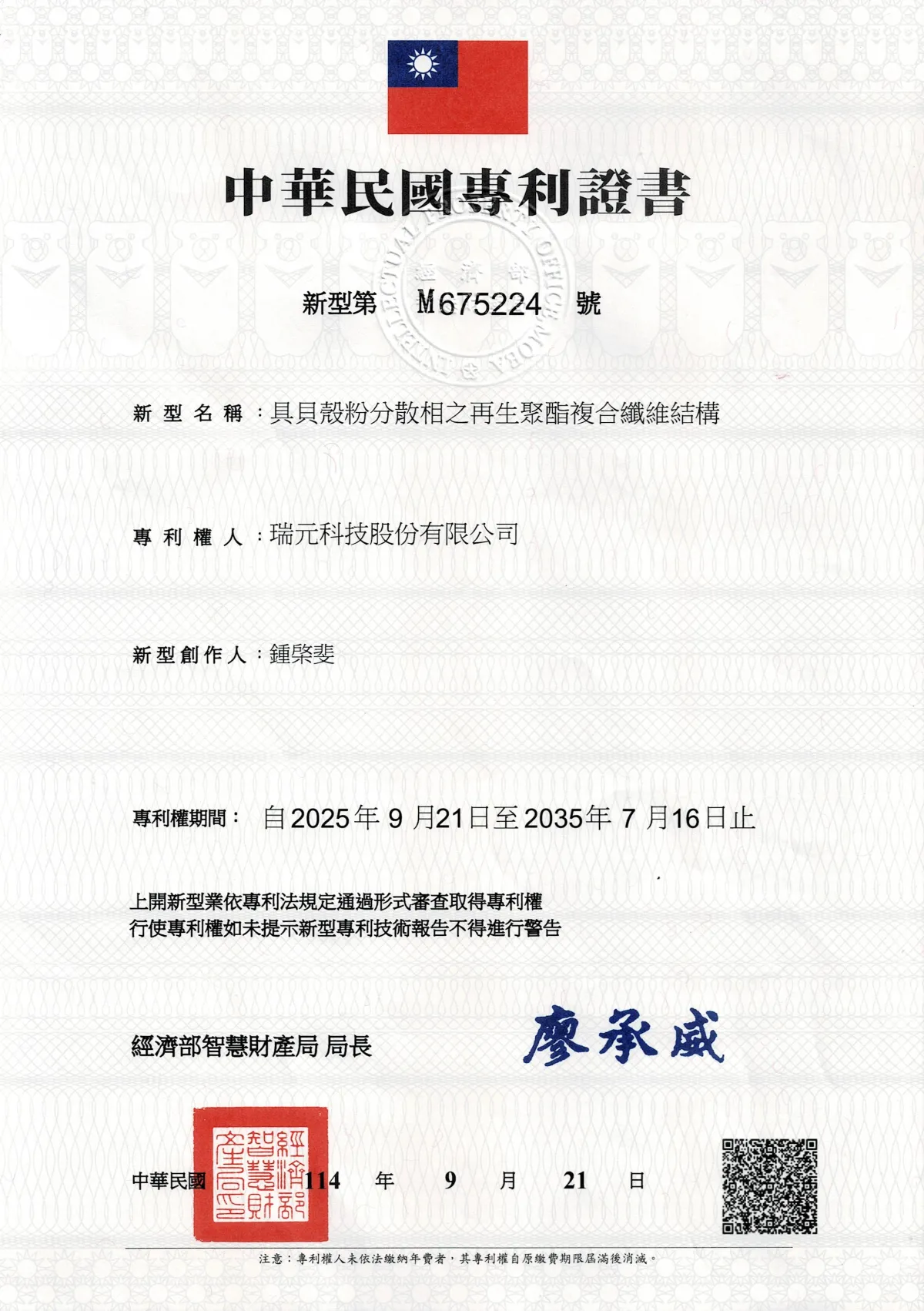

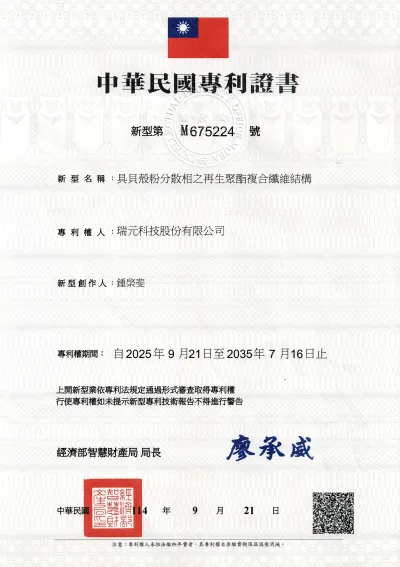

| Taiwan | Issued | M675224 | TWM675224U | Dollarchip Technology Inc. | Recycled polyester composite fiber structure with inorganic shell powder dispersed phase | Google patent link |

You may also like the following patent