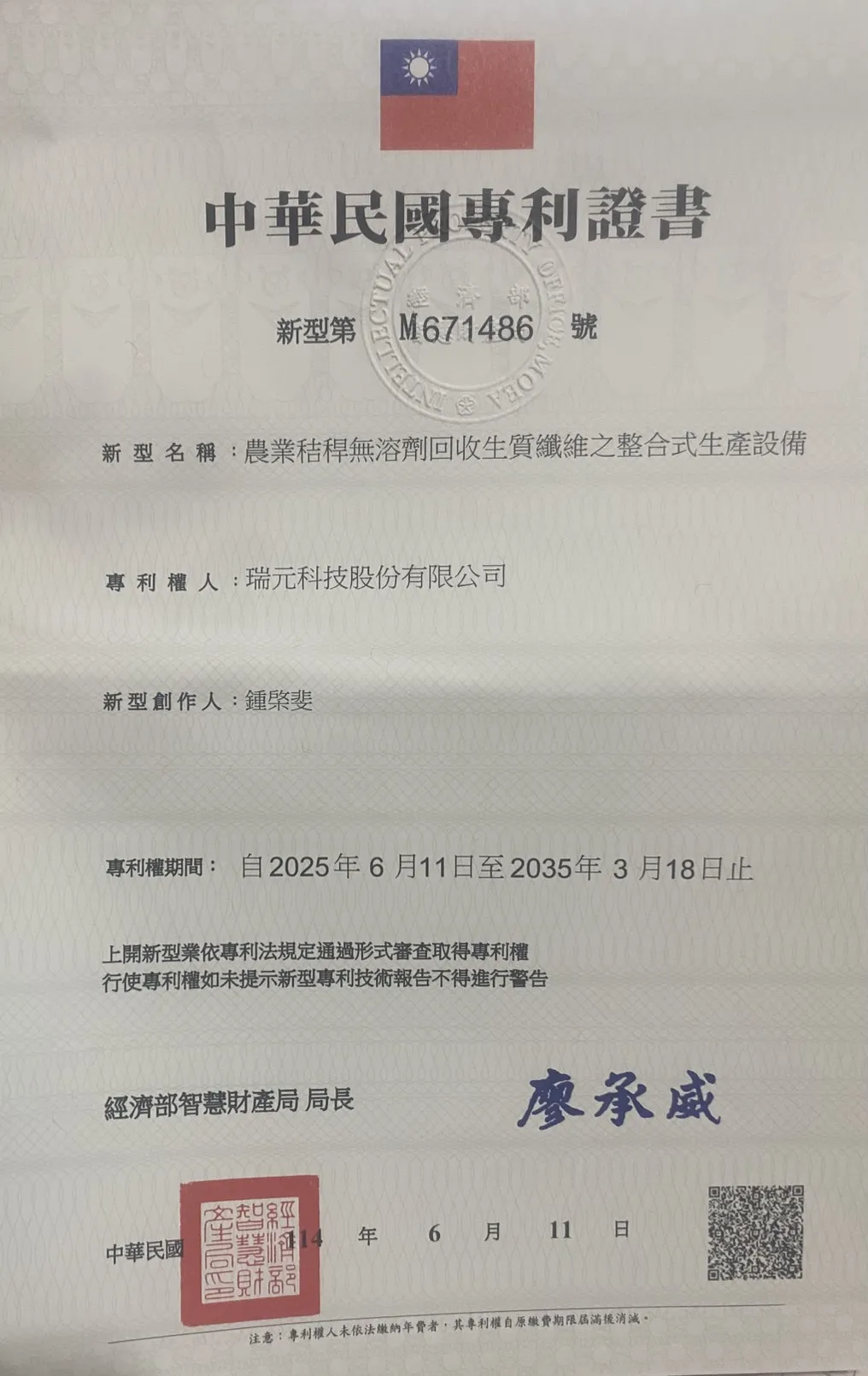

Integrated Production Equipment For Solvent-Free Recycling Of Bio-fiber From Agricultural Straw

This method enables efficient, solvent-free processing of agricultural straw, achieving a fiber extraction rate of over 85%.This is a "green factory" device that can directly convert waste agricultural crop stalks (such as rice straw and wheat straw) into high-quality clothing fibers. It combines cutting, high-pressure steam, ultrasound, and bio-enzyme technologies to extract soft, strong, and textile-compatible bio-fibers without the use of chemical solvents.

Traditional agricultural straw recycling relies on chemical solvents such as strong acids or alkalis to extract fibers, which generates large amounts of polluted wastewater and damages the environment. Furthermore, traditional methods are inefficient, produce coarse fibers that fail to meet the demands of high-quality textiles, and suffer from fragmented production processes lacking automation.

This equipment features a modular design, integrating raw material conveying, pretreatment, fiber extraction, and quality control into a single production line. By using physical and biological technologies such as high-pressure water jets and enzyme catalysis to replace chemical solvents, it achieves a fiber extraction rate of over 85%, producing high-quality fibers with a tensile strength of 350-450 MPa.

The most serious drawbacks of existing technologies are "environmental pollution" and "discontinuous process". This invention achieves true "solvent-free" regeneration technology, completely eliminating the problem of chemical waste liquid. At the same time, it solves the problem of unstable fiber quality in the past, ensuring that each batch of fiber meets textile standards through intelligent monitoring.

Integrated Module Design: Fully automated integration from raw material input to spun fiber output.

High Extraction Rate (>85%): Far exceeding traditional mechanical or single-biological processing methods.

Pure Physical and Biological Extraction: Completely free of acid and alkali solvents, offering significant environmental advantages.

Intelligent Data Management: Equipped with a touch interface and remote monitoring, it can automatically diagnose faults and optimize parameters.

Industries where the invention can be useful?

Sustainable apparel brands,Textile raw material suppliers.An estimate of the total addressable market?

81 BillionPotential Customers/End Users. Who might benefit?

Sustainable apparel brands,Textile raw material suppliers.Documents

-

1766151037529_31.pdf

Actions

Added all portfolio

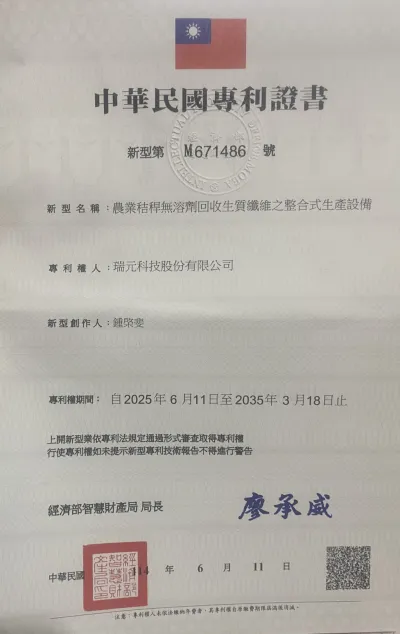

| Country | Current Status | Patent Application Number | Patent Number | Applicant / Current Assignee Name | Title | Google Patent Link |

| Taiwan | Issued | M671486 | M671486 | Dollarchip Technology Inc. | Integrated Production Equipment For Solvent-Free Recycling Of Bio-fiber From Agricultural Straw | Google patent link |

You may also like the following patent