Multipurpose Cutting Machine

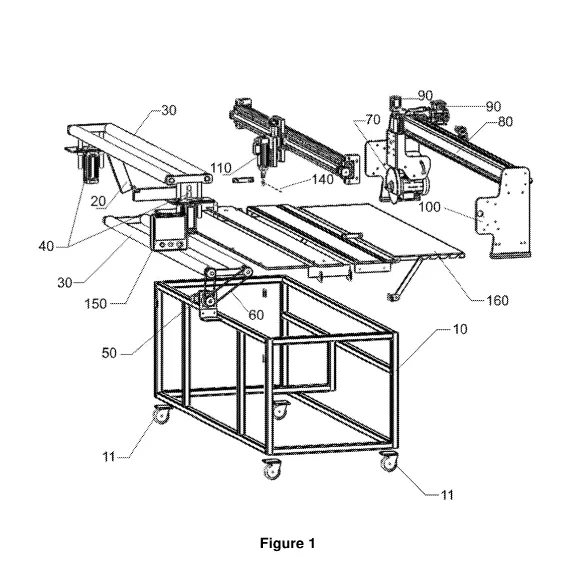

This invention is a Multipurpose Cutting Machine designed to perform several cutting operations in one compact system. It can cut, angle, and groove a wide range of materials such as wood, MDF, acrylic, foamex, aluminum composite, and more. The machine combines the functions of several traditional cutting devices—like CNC routers, miter saws, and grooving machines—into a single device. This not only saves space and reduces equipment costs but also speeds up production by automating various cutting tasks.

Key features include:

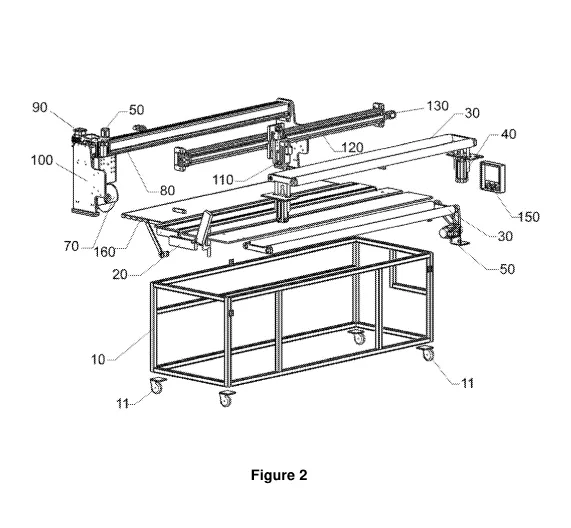

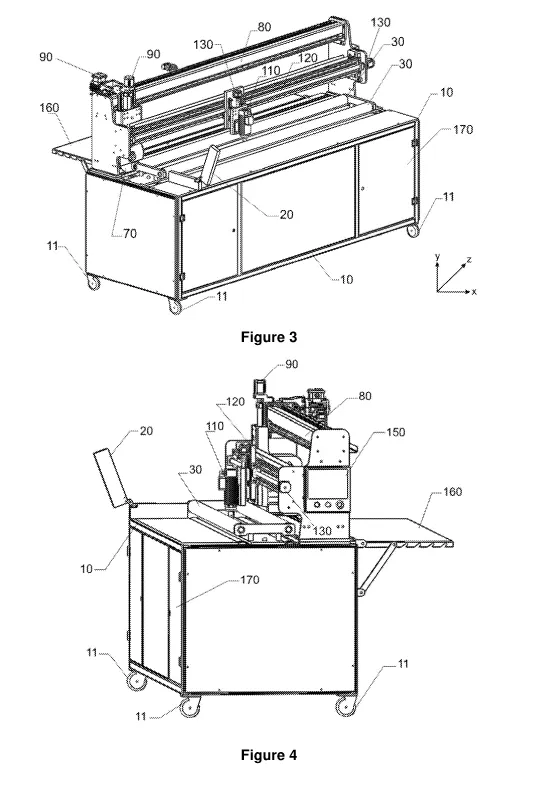

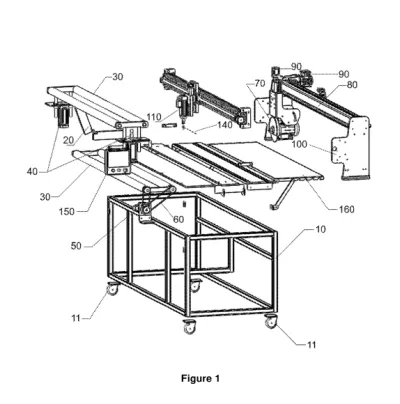

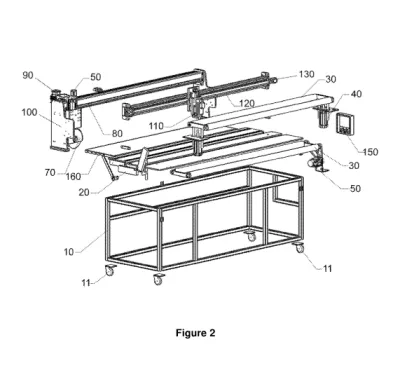

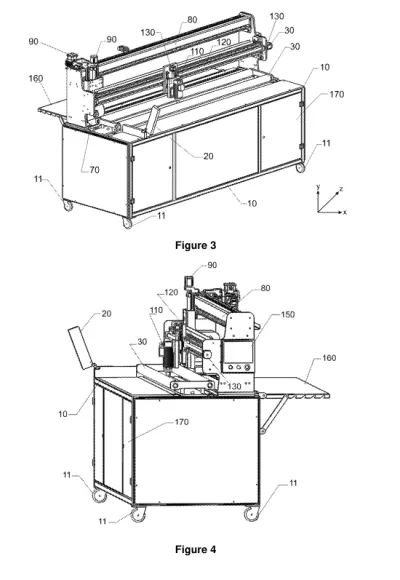

Multi-Axis Cutting: The machine moves in multiple directions (x, y, and z axes) allowing it to perform straight, angled, and grooving cuts.

Integrated Feeding System: A roller group with pneumatic cylinders and a rip fence ensures the material is fed accurately and securely into the cutting area.

Dual Cutting Tools: It features both a circular saw for straight or angled cuts and a cutter for detailed grooving operations.

User-Friendly Operation: An easy-to-use control unit and laser-guided cutting assist the operator in achieving precise cuts.

Space Efficiency: By combining several cutting functions into one machine, it minimizes the space required compared to traditional setups.

Overall, this invention offers an efficient, versatile solution for industries like advertising, furniture making, mold manufacturing, and more, where precise and varied cutting operations are needed.

Problem the Invention Addresses:

In many industries—such as furniture, advertising, mold manufacturing, and construction—different machines are used for cutting and shaping materials like wood, MDF, acrylic, aluminum, and plastic. Typically, one machine is used for straight cuts (like a panel saw), another for angled cuts (like a miter saw), and yet another for grooving (like a CNC router). These machines are often large, expensive, and take up a lot of floor space.

This becomes a big problem when working with large materials like aluminum composite panels, which can be up to 1500x6000 mm in size. Most standard machines are not big enough to handle these sizes. Even when large machines are available, they occupy a huge area, which can be difficult for small to medium-sized workshops to manage.

Another issue is that existing machines are slow and often require manual repositioning of materials between different machines for each type of cut. This wastes time and increases the chance of errors or inconsistent results. Additionally, angled cuts—essential in making frames or certain product assemblies—cannot be done by CNC machines or grooving machines, so a separate miter saw is needed. However, miter saws usually cut only one piece at a time, making them inefficient for bulk operations.

In summary, current solutions are:

Bulky and space-consuming

Costly, requiring multiple separate machines

Not capable of handling large material sizes efficiently

Unable to perform all required cuts (straight, angled, grooving) on a single platform

Slow and labor-intensive

This invention solves all these problems by combining straight cutting, angled cutting, and grooving into one compact, efficient machine. It reduces the need for multiple machines, saves space, lowers costs, speeds up production, and can handle very large materials with ease.

The Invention – The Solution to the Problem:

The invention is a Multipurpose Cutting Machine that solves the challenges faced by industries needing to cut and process large or varied materials. This machine is designed to perform three major functions—straight cutting, angled cutting, and grooving—on a wide range of materials such as wood, MDF, acrylic, foamex, aluminum composite, and more, all within one compact system.

How It Solves the Problem:

All-in-One Functionality:

Instead of using three or more separate machines (CNC router, miter saw, grooving machine), this single machine performs all required cutting tasks. It includes both a circular saw for straight and angled cuts, and a cutter tool for grooving or detailed cuts. This reduces equipment cost and simplifies workflow.

Space Saving:

Traditional machines—especially large CNC machines—take up significant floor space. This invention has a compact design and uses a roller-based material feeding system that eliminates the need for large working platforms, making it ideal even for small workshops.

Supports Large Materials:

The machine is specifically designed to handle large-size panels (up to 1500x6000 mm), which typical machines struggle with. This means that industries working with large composite sheets no longer need oversized, expensive CNC routers.

Efficient Material Handling:

A roller group with a pneumatic clamping system allows smooth and precise movement of materials along the y-axis. This ensures better alignment, more accurate cuts, and faster processing without manual repositioning.

Angled Cutting Capability:

One of the standout features is the ability to perform angled cuts—something most CNC or grooving machines cannot do. The circular saw can be manually or automatically tilted to the required angle, which is essential for creating frames and joints in various industries.

Automated Operation:

A control unit allows the operator to program the cutting steps, saving time and reducing human error. The machine also includes a laser guide for precise marking and cutting visibility.

Portability and Flexibility:

The entire system is mounted on wheels, making it easy to move within a workspace. The adjustable base cover also helps collect processed materials neatly and can be angled for smoother operation.

Conclusion:

This Multipurpose Cutting Machine replaces multiple traditional machines with a single, versatile, and space-efficient solution. It is especially beneficial for industries that require high-precision cutting of large materials in limited spaces. It helps businesses save time, money, and space, while also improving cutting quality and efficiency.

Gap in Prior Art:

In the current state of technology, separate machines are required for different cutting operations:

CNC routers are used for precise and complex cuts and grooving but cannot perform angled cutting.

Miter saws are used for angled cuts but can only process one piece at a time, making them inefficient for bulk cutting.

Grooving machines are used solely for surface grooving and also lack versatility.

Additionally, machines capable of handling very large materials (e.g., aluminum composite sheets up to 1500x6000 mm) are extremely large and occupy significant space—often 10–15 square meters or more.

Existing solutions are space-consuming, expensive, and limited in function. Operators often need to move materials between multiple machines, increasing production time, error risk, and labor costs. No single machine in the prior art could perform straight, angled, and grooving cuts on a wide range of materials in a compact and integrated manner.

For example, TR2012/00800, a cited prior art reference, discloses a miter saw that can only perform single-piece angled cuts, which is insufficient for mass processing or multiple material types.

How the Invention Fills the Gap:

This Multipurpose Cutting Machine fills this significant gap by:

Combining all major cutting operations—straight cutting, angled cutting, and grooving—into a single, integrated system.

Providing the ability to cut large-format materials that cannot be handled by standard CNC routers or miter saws.

Offering precision automation and control through a programmable control unit, enhancing efficiency and reducing manual work.

Saving space and operational costs by eliminating the need for multiple large machines.

Enabling fast, multi-material processing with features like a roller group for automated feeding and a laser guide for precise alignment.

Conclusion:

The invention addresses a clear and pressing gap in the prior art by delivering a compact, versatile, and highly efficient solution for material cutting. It allows industries to replace multiple machines with a single device, optimize floor space, improve cutting accuracy, and increase throughput—an advancement not previously offered by existing technologies.

Unique Features of the Product – Multipurpose Cutting Machine:

All-in-One Cutting Functions:

Combines straight cutting, angled cutting, and grooving in one compact machine—unlike traditional systems that require separate equipment for each operation.

Multi-Axis Movement:

Equipped with components (circular saw and cutter) that move along x, y, and z axes, allowing for precise and flexible cutting from multiple angles and depths.

Large Material Handling:

Capable of processing large-format sheets (up to 1500x6000 mm), addressing limitations of standard CNC routers and saws.

Integrated Roller Feeding System:

A roller group with pneumatic compression and servo motor-driven movement ensures smooth, automated feeding and positioning of materials along the y-axis.

Dual Cutting Tools:

Features both a circular saw for straight and angled cuts and a cutter (which may be a blade, milling tool, or laser) for grooving or fine cuts—mounted on separate motorized beams.

Laser Alignment:

Includes a laser light at the cutter tip for precise visual guidance during material processing.

Space-Efficient and Portable:

Designed with a compact footprint and wheel-based mobility, making it ideal for workshops with limited space.

Adjustable Base Cover:

A tiltable collection platform allows processed materials to slide down and be collected easily, streamlining post-processing.

Centralized Control Unit:

A user-friendly control panel manages all operations, making the machine highly programmable and reducing manual effort.

These distinctive features make the invention a versatile, space-saving, and cost-efficient solution for industries requiring precision cutting across various materials.

Industries where the invention can be useful?

1. Commercial and Market Potential (Simplified for Non-Technical Audience): The Multipurpose Cutting Machine has strong commercial and market potential because it solves common problems faced in many industries—such as the need for multiple machines, lack of space, and time-consuming manual processes. By combining multiple cutting functions into one compact machine, it becomes a valuable tool for a wide range of businesses. Why It Has Market Value: Saves money by replacing multiple machines with one. Saves space in workshops or factories. Increases speed and accuracy, reducing manual errors. Can handle very large materials that most machines cannot. Industries Where the Invention Can Be Useful: Advertising Industry For making lightboxes, display panels, signboards, etc. Furniture Industry For cutting and shaping wood, MDF, acrylic, and composites. Mold Manufacturing For processing aluminum, wood, and steel molds. Aluminum and PVC Industries For cutting profiles and composite panels. Tarpaulin and Awning Industry For cutting large flexible or semi-rigid materials. Cornice and Foam Industry For making decorative or structural foam and cornice elements. Construction and Interior Design For processing materials used in wall cladding, partitions, and décor. Signage and Display Manufacturing For precision cutting of promotional materials. Small Workshops and Fabrication Units Ideal due to its compact size and multiple capabilities. Overall Potential: This invention can be marketed to small businesses, large manufacturers, and custom fabrication units, offering a versatile, cost-saving, and high-precision solution—especially where space and efficiency are priorities.An estimate of the total addressable market?

Furniture Industry Market Size (2024): USD 23.8 billion Projected Growth: Expected to reach USD 44.2 billion by 2033 Advertising Industry Market Size (2024): USD 13.6 billion Projected Growth: Expected to reach USD 32.3 billion by 2030 Dies and Molds Industry Market Size (2025): USD 2.84 billion Projected Growth: Growing at a CAGR of 11.4% from 2025 to 2029 Aluminum Industry Market Size (2024): USD 17.5 billion Projected Growth: Expected to reach USD 35 billion by 2035 PVC Industry Market Size (2025): USD 3.70 billion Projected Growth: Expected to reach USD 5.45 billion by 2033 Digital Signage Industry Market Size (2024): USD 1.06 billion Projected Growth: Expected to reach USD 1.91 billion by 2030 Total Addressable Market (2025 Estimate): By aggregating the market sizes of these industries, the estimated total addressable market for the Multipurpose Cutting Machine in India for 2025 is approximately USD 62.3 billion.Potential Customers/End Users. Who might benefit?

Signboard makers Furniture manufacturers Sheet metal and ACP fabricators Modular kitchen and interior fit-out providers Industrial designers and engineers Small workshops with diverse material needs Educational institutions (technical training labs)Actions

Added all portfolio

| Country | Current Status | Patent Application Number | Patent Number | Applicant / Current Assignee Name | Title | Google Patent Link |

| India | Continue | 202517011407 | N/A | Sanaullah Ashrafi | MULTIPURPOSE CUTTING MACHINE | Google patent link |

You may also like the following patent